Type: LDT series Tire Shredding machine

Power(kw): 15 – 160

Capacity(t/h): 5 – 60

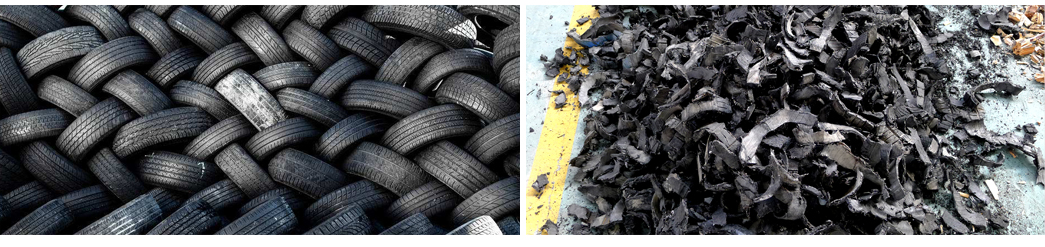

Appication: Used for waste tyre, rubber pipe, various scrap rubber products and so on.

Heavy rotary knife with high crushing efficiency. The knives are all made of alloy steel, sturdy and durable, with a long service life.

Adopting microcomputer (PLC) automatic control, and having such control functions as start, stop, reverse and overload automatic reverse.

The equipment has the characteristics of low rotating speed, high torque, low noise and the dust achieving the environmental standards.

Easy adjustment, low maintenance cost, economic durability.

The thickness of the shredder blade is divided into 15mm, 20mm, 40mm, 50mm, 75mm, 100mm, can select the blade according to the particle size after crushing.

Waste tire-Hook debeader-Separate-Primary grinding-Final grinding

Note: According to the requirements of final size, equipment can be customized.

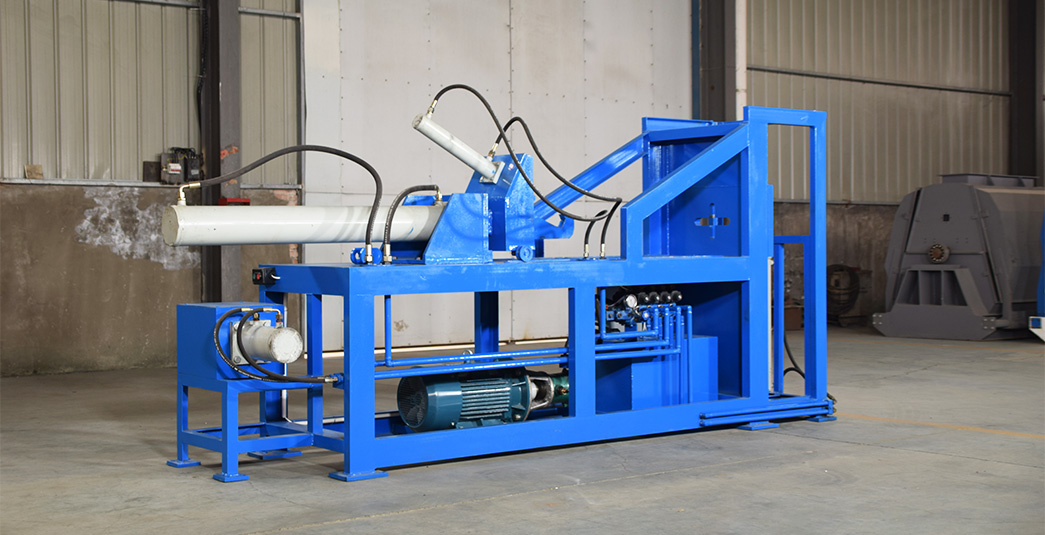

Hook debeader machine is a special equipment for extracting the steel wire from the old tires.

The equipment is suitable for recycling and reprocessing of used tires. After the recycling and processing of waste tires, the production of rubber particles can be used as raw materials for renewable rubber products.

The tire hook debeader is an important part in the process of waste tire. It can extract the thick steel wire in the tire, which is beneficial to the next crushing process.

The compact design of the device, rack, hook, knife and cylinder movement system are heavy type. Easy to meet production process requirements.

The separator is a special equipment to separate rubber and wire from used tires. The equipment is suitable for recycling and reprocessing of used tires. Through recycling and processing of waste tires, rubber granules are produced, which can be used as raw materials for renewable rubber products.

The tire wire separator is an important part in the process of waste tire. It can separate the steel wire from the tire and produce full rubber granulars from waste tires and to ensure the quality of rubber granular.

The compact design of the steel wire separator machine , rack, hook, knife and cylinder movement system are heavy type. Easy to meet production process requirements.

| Model | Main Shaft (pcs) | Blades Size (mm) | Blades (pcs) | Reducer (sets) | Motor Power (kw) | Main Shaft Speed (r/min) | Dimensions (mm) |

| LDT600 | 2 | Φ250*10 | 48 | 400*2 | 15*2 | 18-25 | 1450*870*2200 |

| 2 | Φ250*20 | 24 | 400*2 | 15*2 | 18-25 | 1450*870*2200 | |

| LDT800 | 2 | Φ250*20 | 32 | 400*2 | 30*2 | 18-25 | 2150*870*2200 |

| 2 | Φ250*30 | 18 | 650*2 | 30*2 | 18-25 | 3400*1250*2200 | |

| LDT1000 | 2 | Φ350*30 | 28 | 650*2 | 37*2 | 18-25 | 3400*1250*2200 |

| 2 | Φ350*40 | 20 | 750*2 | 37*2 | 18-25 | 4150*1250*2200 | |

| LDT1200 | 2 | Φ350*30 | 38 | 650*2 | 55*2 | 18-25 | 4150*1250*2200 |

| 2 | Φ350*40 | 28 | 750*2 | 55*2 | 18-25 | 4150*1250*2200 | |

| LDT1500 | 2 | Φ400*40 | 36 | 750*2 | 75*2 | 18-25 | 4150*1250*2200 |

| 2 | Φ400*50 | 28 | 850*2 | 75*2 | 18-25 | 4150*1250*2200 | |

| LDT2000 | 2 | Φ530*50 | 38 | 850*2 | 90*2 | 18-25 | 5250*1780*2200 |

| 2 | Φ600*60 | 32 | 850*2 | 90*2 | 18-25 | 5250*1780*2200 | |

| LDT2500 | 2 | Φ600*60 | 60 | 1000*2 | 110*2 | 18-25 | 7500*3200*3800 |

| 2 | Φ600*75 | 50 | 1000*2 | 110*2 | 18-25 | 7500*3200*3800 | |

| LDT3000 | 2 | Φ600*75 | 56 | 1200*2 | 132*2 | 18-25 | 8600*3500*4000 |

| 2 | Φ600*100 | 44 | 1200*2 | 132*2 | 18-25 | 8600*3500*4000 |

Overseas marketing outsourcing services for small and medium-sized enterprises.